产品分类

Elgiloy(40Co-20Cr-16Fe-15Ni-7Mo)埃尔吉洛伊非磁性合金钴铬镍合金化学成分物理性能

Elgiloy®

W.Nr 2.4711

Applications

Springs, seals, semiconductor components, orthodontics, medical devices, surgical implants, satellite communications equipment, and weapons systems.

Description

Elgiloy® is a non-magnetic Cobalt-Chromium-Nickel-Molybdenum alloy having a unique combination of very high strength while maintaining excellent formability, excellent corrosion resistance, and high fatigue strength. Additional strength increases of up to 25% can be achieved through aging cold reduced material. Elgiloy® is highly resistant to sulfide stress corrosion cracking, and as a result is the alloy of choice in the most demanding sour well environments. In seawater, Elgiloy® is virtually immune to crevice and stress corrosion and pitting even at the highest strength levels. Elgiloy® performs across a wide range of temperatures: from cryogenic up to 850°F (454°C).

Industries Supplied

Oil & Gas Extraction, Medical, Dental, Aerospace, Defense, Space Exploration and Watch making.

Nominal Composition

C: 0.15 max

Mn: 1.5 - 2.5

Si: 1.20 max

P: 0.015 max

S: 0.015 max

Cr: 19.0 - 21.0

Ni: 14.0 - 16.0

Co: 39.0 - 41.0

Mo: 6.0 - 8.0

Be: 0.10 max

Fe: Balance

Physical Properties

Density: 0.30 lb/in3, (8.30 g/cm3)

Modulus of Elasticity (E):

At 70°F (20°C): 27.0 x 103 ksi (190 GPa)

Modulus of Rigidity (G):

At 70°F (20°C): 11.0 x 103 ksi (76 GPa)

Coefficient of Expansion:

8.4 µin/in.-°F (70°F to 600°F)

15.2 µm/m-°C (20°C to 300°C)

Electrical Resistivity: 39.21 µΩ.in, (99.6 µΩ.cm)

Thermal Conductivity: 86.5 Btu-in/ft2hr-°F, (12.5 W/m-K)

Applicable Specifications

Strip and Foil: AMS 5876, ASTM F1058, NACE MR 0175 & MR 0103, ISO 5832-7

Typical Mechanical Properties – Spring Applications

- Annealed

- Heat Treatment: Per AMS 5876

- Tensile Strength: 100 ksi min (690 MPa)

- Suggested Operating Conditions: -300°F to 850°F (-184°C to 454°C)

- Spring Temper

- Heat Treatment: No Heat Treatment

- Tensile Strength: Up to 310 ksi (2100 MPa)

- Suggested Operating Conditions: -300°F to 850°F (-184°C to 454°C)

- Spring Temper + Aged

- Heat Treatment: After cold rolling. Age: Per AMS 5876, Nace MR 0175

- Tensile Strength: Up to 380 ksi (2600 MPa)

Suggested Operating Conditions: -300°F to 850°F (-184°C to 454°C)

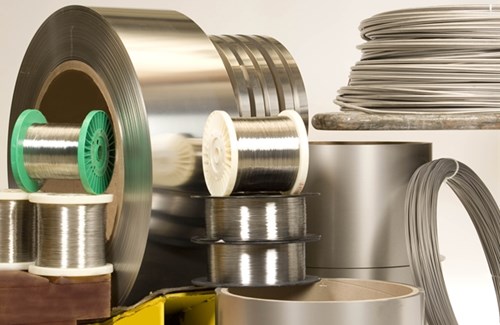

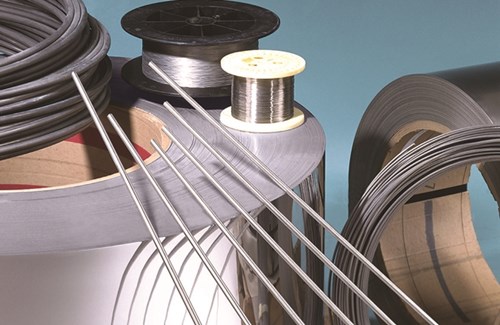

作为值得信赖的合作伙伴和高品质金属合金的半成品供应商,艾荔艾拥有完善的服务体系和专业的团队。在同客户交易的过程中,我们力求根据不同的应用需求将我们的产品做到精益求精。针对当前和未来的市场需求,艾荔艾致力于为客户提供最佳的金属材料解决方案。

AILIAI has been a reliable partner and supplier of sophisticated and high-quality semi-finished products maed of alloys. In dialogue with our customers, we optimise our products to meet the specific application requirements. AILIAI develops the best alloy material solutions for current and future challenges.

获取更多我们供应的合金和服务信息,请致电086-021-67660801或发电子邮件kefu@ailiaigroup.com联系我们,您也可以通过微博和微信和我们互动。

For more information on the alloys and services that we supply, call us at 086-021-67660801 or email us at kefu@ailiaigroup.com. You can also get in touch on social media, we are constantly active on Weibo and Weixin.