产品分类

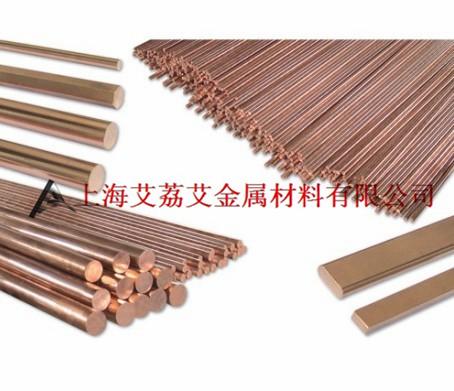

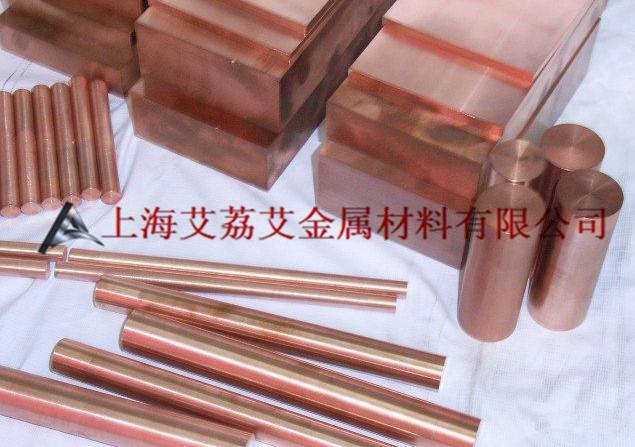

TCr0.5,C18400铬铜合金板棒化学成分力学性能物理性能

|

Arsenic |

0.005 max |

|

|

Chromium |

0.4 - 1.2 |

|

|

Iron |

0.15 max |

|

|

Lithium |

0.05 max |

|

|

Phosphorus |

0.05 max |

|

|

Remainder Total |

Cu, including Ag, + sum of named elements |

|

|

Silicon |

0.1 max |

|

|

Zinc |

0.7 max |

Principal Design Features High Copper Alloy, Chromium Copper. Moderately high elevated strength, conductivity 80% IACS.

Applications Used for resistance welding equipment components: tips, clamps, wheels; other electrical and mechanical power transmission devices, circuit breaker parts, and high-strength fasteners for elevated-temperature service.

Machinability The machinability rating of this alloy is 20. (Where Alloy 360 FC Brass is 100).

Welding Soldering is rated as "good", brazing is rated as "good", oxyacetylene welding is "not recommended", gas shielded arc welding is rated as "good", coated metal arc welding is "not recommended", spot welding is "not recommended", seam welding is "not recommended", and butt welding is rated as "fair".

Forging The hot forgeability rating of this alloy is 80. (Forging brass=100). The recommended hot working temperature for this alloy is between 1400-1600 F.

Hot Working This alloy's capacity for being hot formed is rated as "good".

Cold Working The capacity for cold working this alloy is rated as "excellent".

Annealing The annealing temperature for this alloy is unknown.

Physical Data :

Density (lb / cu. in.) 0.321

Electrical Resistivity (microhm-cm (at 68 Deg F)) 13

Melting Point (Deg F) 1958

Mean Coeff Thermal Expansion 9.8

Modulus of Elasticity Tension 17000

以上资料由上海艾荔艾金属材料有限公司提供,欢迎新老客户来电洽购。

本文来自上海艾荔艾金属材料有限公司http://www.shailiai.com,转载请注明出处。