产品分类

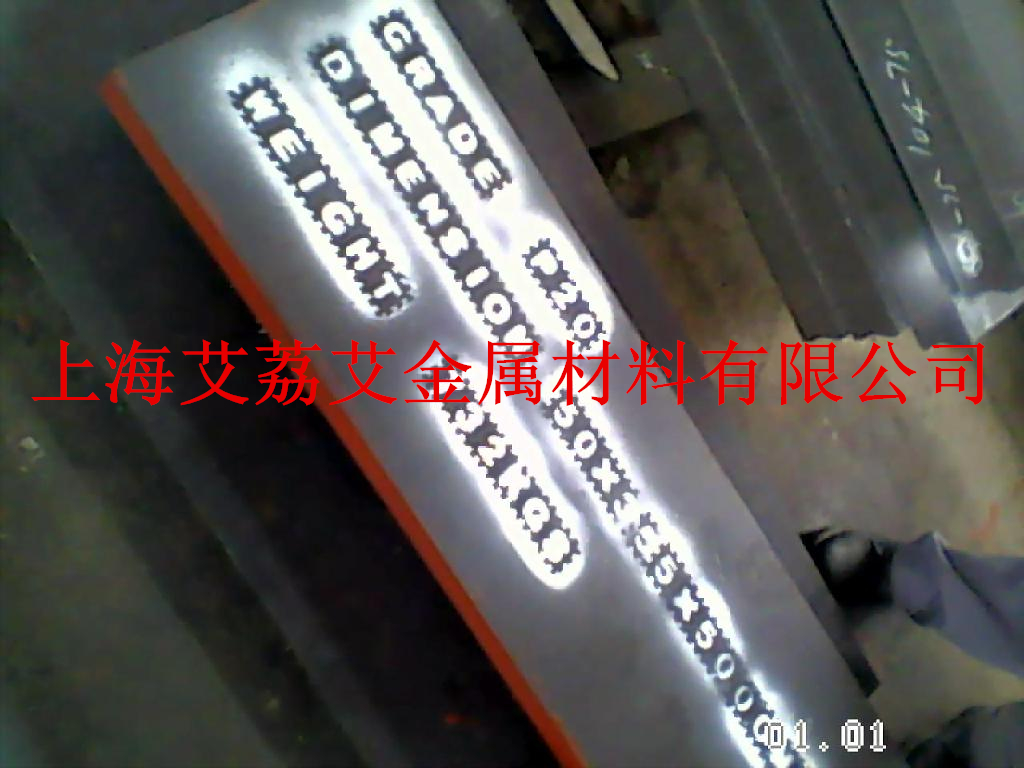

P20预硬化塑料模具钢3Cr2Mo\1.233\DIN 1.2311\ASSAB 618\P20H\P20Ni塑胶模具钢P20 plastic mold steel

|

c

|

si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

Ni

|

|

0.28-0.4

|

0.2-0.8

|

0.6-1

|

≤0.03

|

≤0.03

|

1.4-2

|

0.3-0.55

|

0.05-0.10

|

|

项目

|

加热温度/℃

|

开锻温度/℃

|

终锻温度/℃

|

冷却

|

|

钢锭

|

1180~1200

|

1130~1150

|

≥850

|

坑冷

|

|

钢坯

|

1120~1160

|

1070~1110

|

≥850

|

砂冷或缓冷

|

Steel Standard and Grade

AISI P20; DIN 1.2311; ASSAB 618; GB 3CrMO2

P20 is a pre-hardened high tensile tool steel which offers ready machineability in the hardened and tempered condition, therefore does not require further heat treatment. This eliminates the risks, cost, and waiting time of heat treatment thus avoiding the associated possibility of distortion or even cracking. Subsequent component modifications can easily be carried out.

1. Features:

P20, American AISI standard pre-hardened plastic mold steel, good machining performance, excellent polishing performance, a certain toughness, can be carburized, surface hardness is up to 65HRC after carburizing quenching, with higher hot hardness and wear resistance.

2. Supply Condition: Pre-hardened, Hardness 30~35HRC.

3. Transformation temperature(Approx): AC1=770° C, AC3=825° C, Ar1=640° C, Ar3=760° C, Ms=300° C, Mf=120° C

4. Thermal processing specification: Heating temperature 1100~1150° C, Beginning forging temperature 1050~1100° C, Ending forging temperature ≥ 850° C, then air cooling.

5. Annealing specification: Heating temperature 1100~1150° C, holding time 2 ~ 4 h, the isothermal temperature 720° C, holding time 4 ~ 6h, furnace cooling to 500° C, released, then air cooling.

6. Quenching and Tempering specification:

Quenching temperature 860~870° C, oil quenching, Tempering temperature 540~580° C, hardness 30~35HRC.

7. P20 Plastic Mould Steel of Applications:

1) Thermoplastic injection mold and extrusion mold

2) Thermoplastic blowing mold

3) Main parts of heavy-duty mold

4) Structural fabrications

5) Usually used for manufacture of television casing, washing machine, refrigerator inner shell, and water-pot, etc.

| Chemical Composition | C | Si | Mn | Cr | Mo | P | S |

| % | 0.28~0.40 | 0.20~0.80 | 0.60~1.00 | 1.40~2.00 | 0.30~0.55 | ≤ 0.030 | ≤ 0.030 |

以上资料由上海艾荔艾金属材料有限公司提供,欢迎新老客户来电洽购。