Aluminium alloy AlMg3/5754 has excellent corrosion resistance especially to seawater and industrially polluted atmospheres.It has higher strength than 5251. This high strength makes 5754 highly suited to flooring applications.

Aluminium alloy AlMg3/5754 has excellent corrosion resistance especially to seawater and industrially polluted atmospheres.

It has higher strength than 5251. This high strength makes 5754 highly suited to flooring applications.

Applications

5754 is typically used in:

~ Treadplate

~ Shipbuilding

~ Vehicle bodies

~ Rivets

~ Fishing industry equipment

~ Food processing

~ Welded chemical and nuclear structures

Please note that Mechanical Properties shown are for W19/H111 temper.

Chemical Composition

Spec: BS EN 573-3:2009

Alloy 5754

Chemical Element % Present

Manganese (Mn) 0.0 - 0.50

Iron (Fe) 0.0 - 0.40

Magnesium (Mg) 2.60 - 3.60

Silicon (Si) 0.0 - 0.40

Chromium (Cr) 0.0 - 0.30

Copper (Cu) 0.0 - 0.10

Manganese + Chromium (Mn+Cr) 0.10 - 0.60

Other (Each) 0.0 - 0.05

Others (Total) 0.0 - 0.15

Titanium (Ti) 0.0 - 0.15

Zinc (Zn) 0.0 - 0.20

Aluminium (Al) Balance

Properties

Physical Property Value

Density 2.66 g/cm³

Melting Point 600 °C

Thermal Expansion 24 x10^-6 /K

Modulus of Elasticity 68 GPa

Thermal Conductivity 147 W/m.K

Electrical Resistivity 0.049 x10^-6 Ω .m

Spec: BS EN 485-2:2008

Sheet - 0.2mm to 6.00mm

Mechanical Property Value

Proof Stress 60 Min MPa

Tensile Strength 160 - 200 MPa

Hardness Brinell 44 HB

Elongation A50 mm 12 Min %

Alloy Designations

Alloy 5754 also corresponds to the following standard designations and specifications but

A95754

Al Mg3

Al 3.1Mg Mn Cr

AW-5754

Temper Types

The most common tempers for 5754 aluminium are shown below with H114 & H111 being the most common treadplate temper

• O - Soft

• H111 - Some work hardening imparted by shaping processes but less than required for H11 temper

• H22 - Work hardened by rolling then annealed to quarter hard

• H24 - Work hardened by rolling then annealed to half hard

• H26 - Work hardened by rolling then annealed to three-quarter hard

• H114

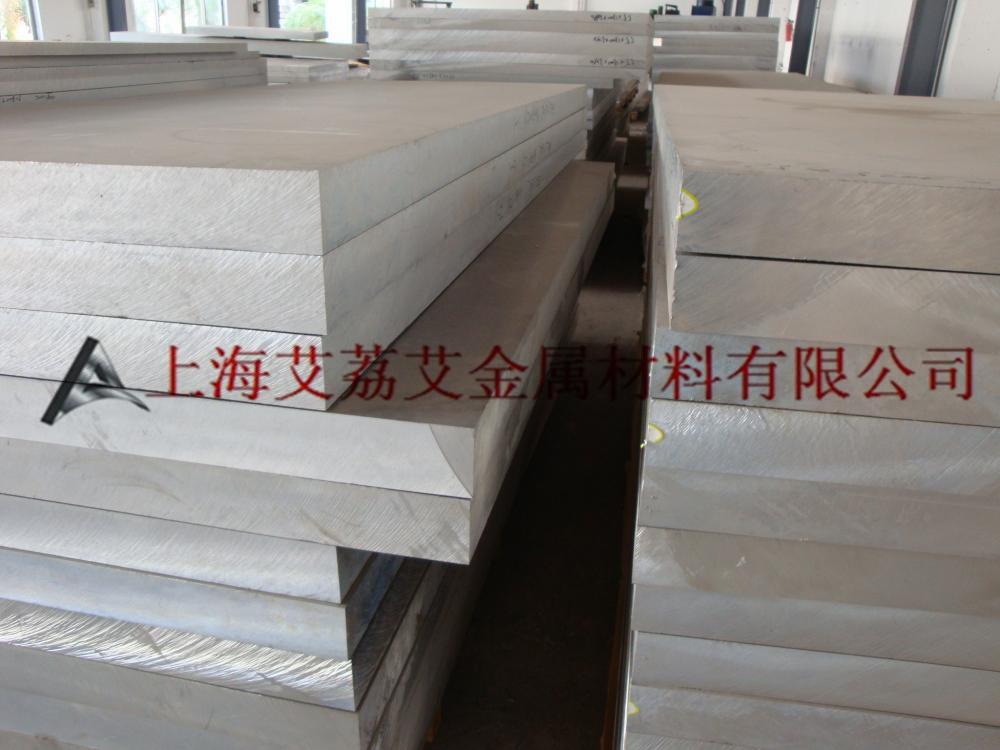

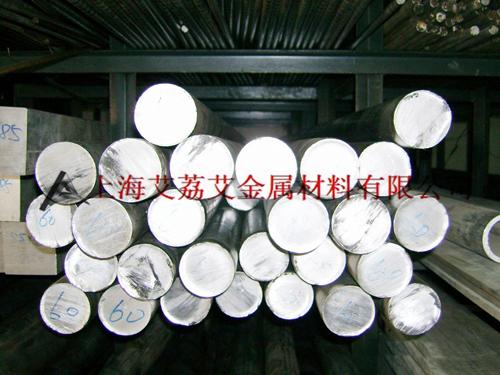

Supplied Forms

Alloy 5754 is typically supplied as treadplate

• Plate

• Sheet

• Treadplate/Patterened Sheet

Weldability

Weldability – Gas: Excellent

Weldability – Arc: Excellent

Weldability – Resistance: Excellent

Brazability: Poor

Fabrication

Workability – Cold: Very good

Machinability: Average

作为值得信赖的合作伙伴和高品质金属合金的半成品供应商,艾荔艾拥有完善的服务体系和专业的团队。在同客户交易的过程中,我们力求根据不同的应用需求将我们的产品做到精益求精。针对当前和未来的市场需求,艾荔艾致力于为客户提供最佳的金属材料解决方案。

AILIAI

has been a reliable partner and supplier of sophisticated and high-quality

semi-finished products maed of alloys. In dialogue with our customers, we

optimise our products to meet the specific application requirements. AILIAI

develops the best alloy material solutions for current and future

challenges.

获取更多我们供应的合金和服务信息,请致电086-021-67660801或发电子邮件kefu@ailiaigroup.com联系我们,您也可以通过微博,微信,领英,XING,脸书和推特与我们互动。

For

more information on the alloys and services that we supply, call

us at

086-021-67660801 or email us at kefu@ailiaigroup.com. You can also get in touch

on social media, we are constantly active on Weibo, Weixin, LinkedIn, XING,

Facebook and Twitter.