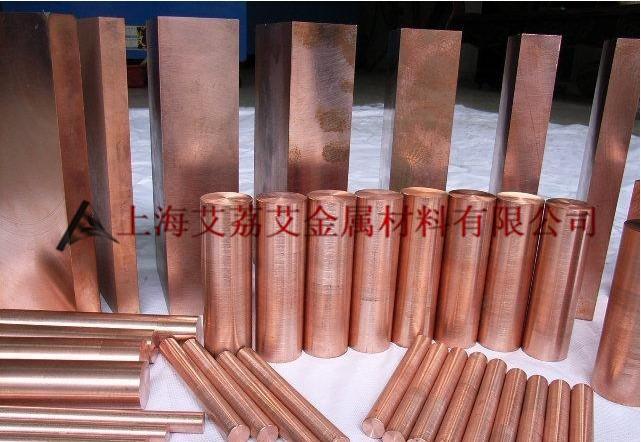

产品分类

TCr1,C18200,CuCr1铬铜合金板棒化学成分力学性能物理性能

Copper Alloy No. C18200

Chromium Copper , RWMA Class 2 Chrome Copper

Chemical Composition % by weight

Copper (incl. silver) Iron Chromium Silicon Lead 99.1 Nominal .10 Maximum .60 Minimum .10 Maximum .05 Maximum

Applications

Resistance welding machine electrodes, seam welding wheels, electrical switch gear, electrode holder jaws, cable connectors, current carrying arms and shafts, circuit breaker parts, arcing and bridging parts, grid side rods in electron tubes, molds, spot welding tips, flash welding electrodes, electrical and thermal conductors requiring greater strength than copper, switch contacts.

Mechanical Properties

Typical for .500" rod solution heat treated and aged (500C-3 hrs.)

Hardness* Rockwell B Scales 70 Tensile Strength** KSI 70 Yield Strength** KSI 55 Elongation** % in 2 inch 21 *Hardness conversions are approximate

**Test values are nominal approximations and depend on specimen size and orientation.

Physical Properties

Thermal Conductivity BTU/ (sq ft-ft-hr-F) 187 Specific Heat BTU/lb/篎 @ 68F .090 Thermal Expansion Per 癋 from 68 F to 212 F .0000098 Density lb/cu in @ 68 F .321 Electrical Conductivity* (Annealed) % IACS @ 68 F 80 Modulus of Elasticity KSI 17,000 **Volume basis

Fabrication Properties

Capacity for being cold worked Excellent Capacity for being hot formed Good Hot forgeability rating (forging brass=100) 80 Hot working temperature 1500-1700 F or 800-925 C Machinability rating (Free Cutting Brass=100) 20 Suitability for being joined by: Soldering/Good Brazing/Good Oxyacetylene Welding/Not Recommended Gas Shielded Arc Welding/Good Coated Metal Arc Welding/Not Recommended Resistance Welding Spot/Not Recommended Seam/Not Recommended Butt/Fair The values listed above represent reasonable approximations suitable for general engineering use. Due to commercial variations in composition and to manufacturing limitations, they should not be used for specification purposes. See applicable A.S.T.M. specification references.