产品分类

DF6Co(W6Mo5Cr4V2Co2)含钴耐磨高速钢DF6(M2\SKH51)/DF6M(SKH54)一胜特高速工具钢化学成分力学性能

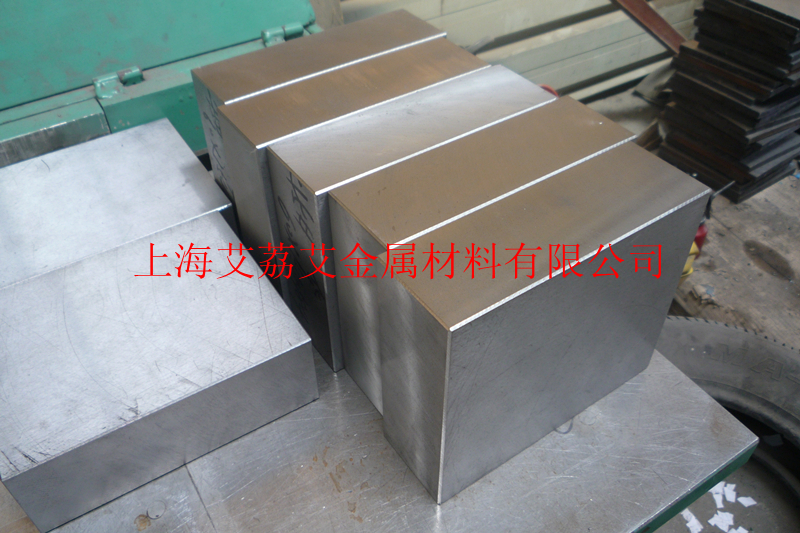

● DF6Co是一胜特在DF6(M2)基础上推出的耐磨性更高,红硬性更好,仍保持高韧性的含钴高速钢。

● DF6Co更高耐磨性主要源于适度的碳饱和度。(控制在M2C之间),提高了DF6Co的使用硬度从而更耐磨,同时又保持了M2钢的高韧性。

● DF6Co通过适量钴的加入获取了更好的红硬性。钴的加入有肋使用状态的稳定和细晶体的保持,有效提升了钢的回火稳定性,同时保持高的韧性。

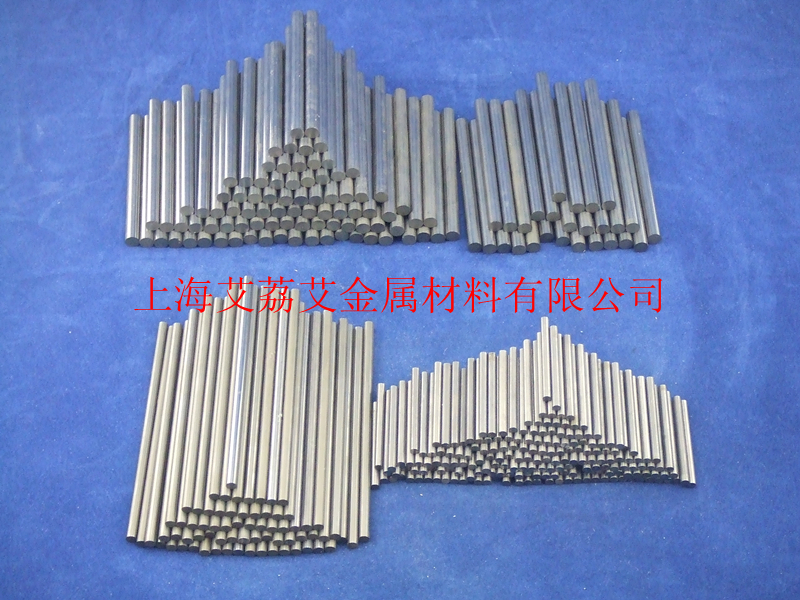

● 用途:

立铣刀、锯片铣刀、超硬车刀、机用丝锥、切割圆锯片等各类刀具。加工不锈钢及钛合金有比M2更高的切削效率。

以上资料由上海艾荔艾金属材料有限公司提供,欢迎新老客户来电洽购。

Chemical Composition

C

Si

Mn

Cr

W

Mo

V

Co

(Typical analysis %)

0.90

0.38

0.35

4.10

6.00

4.80

1.80

1.40

End mill, Slitting saws, extra hard lathe bit, machine tap, circular saw blades, etc. When processing stainless steel and titanium alloy, DF6Co has better efficiency than M2

| Cutting tool | End mill, side and face cutter |

Slitting saws blade | Extra hard lathe bit | Screw Tap | H.S.S. Circular Saw Blade |

| Workable hardness | 65-66 | 64-66 | 65-67 | 64-66 | 64-66 |

- Basing on DF6 (M2), EAST TOOL introduced cobaltic high speed steel DF6Co, which has stronger wearlessness, better red hardness, and keep high tenacity.

- Moderate saturation degree of carbon (keep between M2 and high carbon M2C), improve the workable hardness of DF6Co, and keep the high tenacity of M2 steel.

- After adding in a right amount of cobalt, DF6Co gets better red hardness. Adding cobalt contributes to stability of carbide and maintenance of fine grain in work, improves the tempering stability of steel and keeps in state of strong wearlessness.